Lughnasa Honey Moon

BTW: Kate finished bottling this afternoon and we have 85 pound jars of honey with two supers and some honey still on the colony.

Our hive patroness, Artemis.

Lughnasa Honey Moon

BTW: Kate finished bottling this afternoon and we have 85 pound jars of honey with two supers and some honey still on the colony.

Our hive patroness, Artemis.

Lughnasa Honey Moon

Got my second pneuma-vax since I got one before age 65. That was fun.

Loki’s Children has begun to occupy front space in my mind, turning to it in the morning now when I’m at my best. Work in the garden early, while it’s still moderately cool, then inside for the a.m.

After Missing has gone through its final paces with beta readers and Robert Kleim, I’ll begin seeking agents. In fact I plan to develop a list this week, so I’ll be ready when a final draft is.

Two things to do this week in addition to others: 1. Make candles. 2. Finally install our CD changer that we filled up a couple of months ago.

Lughnasa Honey Moon

Bees make several products in addition to honey: propolis (the sticky stuff bees use to seal up the hive), royal jelly (fed to larvae to turn them into queens) and bees wax (the six sided honey comb). All of them have various uses, but the only thing I’ve gathered after the honey is bees wax. Up until this year I had never rendered it, but after reading and watching a few videos, I hit on the easy method I’ve shown you in previous posts.

Here is the result:

Beautiful. The smell is one you’d like to have in your house year round sweet, fresh, clean. Next stop, candles. I might make some furniture polish, too.

Lughnasa Honey Moon

The environmental community has a new addition, Arthur Levi Neilsen, born today. 8.5 pounds, 21.5 inches to Greg Neilsen and Margaret Levin. Margaret is the executive director of the Northstar Chapter of the Sierra Club. Congratulations to Greg and Margaret!

Grocery shopping today for the first time in a long time. Kate’s been handling that for a while, seeking deals quite successfully and saving us money.

It’s been a domestic week for team Olson-Ellis with the honey extracted and partially bottled, excess books taken to Half-Price books and sold and multiple cans of paint and other hazardous waste accumulated over many years taken to the Anoka County hazardous waste pickup.

Now kicking back and enjoying the slow ride toward misplaced heat. The heat has, however, made rendering the wax from our cappings a breeze. We have a tupperware container full of bright yellow, clear, wonderful smelling wax. A treat.

Lughnasa Honey Moon

Quiet has fallen here, though the temperature has not. 9 pm in late August and the temp outside is 75, the dewpoint 65. And we’re heading into a week of high dewpoints and temps above 90, Friday right now comes in at 96. This is the time when we start to cool down, head toward fall, this year, no. As Paul Douglas, local meteorologist said in a recent column, “Mother nature needs to be medicated.”

As things calm down and drift back toward normal, I’ll look at the edits the copy editor made on my sample pages. He charges $20 an hour and estimates 50 hours for the book, so that’s $1,000. That’s a lot, yes, but to put the final polish on the manuscript before it goes to agents and publishers, probably worth it. But I have to believe he’ll deliver. That’s why I want to check the edits carefully.

After the nap today, I began to feel rested again. The bee vacation has begun to recede though I did spend some time today looking at candle making videos. The candle mold I purchased makes 8 tapers. I also bought 100 feet of wick, so I’m ready to go as soon as the wax rendering is complete.

Lughnasa Honey Moon

I’ve been on vacation. A bee vacation. Kate and I started prepping on Tuesday, extracted on Wednesday, cleaned up and dried honey on Thursday and spent some of this morning finishing clean up and rendering wax.

on Wednesday, cleaned up and dried honey on Thursday and spent some of this morning finishing clean up and rendering wax.

This cappings tank functions as a solar oven, letting the honey drip down from the cappings through slots and holes in a tray that sits inside the tank and under the lid.

Yesterday I watched a youtube video on wax rendering and a guy used a two-hundred dollar solar oven for separating wax from impurities. I thought, hey. I can do this with my cappings tank.

So I copied his screen mesh covered with a layer of paper towel, put that on the tray under the lid and put the cappings and gathered wax from other times on it. And voila! Pure yellow wax is now gathering, floating on water in the tank, the only energy source the sun. No pots, no double boilers, no crock pots, no fancy insulated tanks.

Four years ago I bought candle molds with the intention of making, well, candles. I have a new skill learning resistance when I’m learning too many things at once and the wax rendering, candle making hit my barrier every time we finished extracting. Too weary.

This time though Kate and I had the extracting figured out, made it work, so I could learn how to dry honey and render wax. Next is making candles from the wax. With the rendering so simple, it will become a regular part of the extracting process. As will candle making.

So we learned two new skills this extracting season.

Lughnasa Honey Moon

This old body. It takes longer to recuperate. Yesterday I wasn’t sure I’d feel fine ever again. Today, I’m back. Lifting, standing, bending all those things Warren said are good

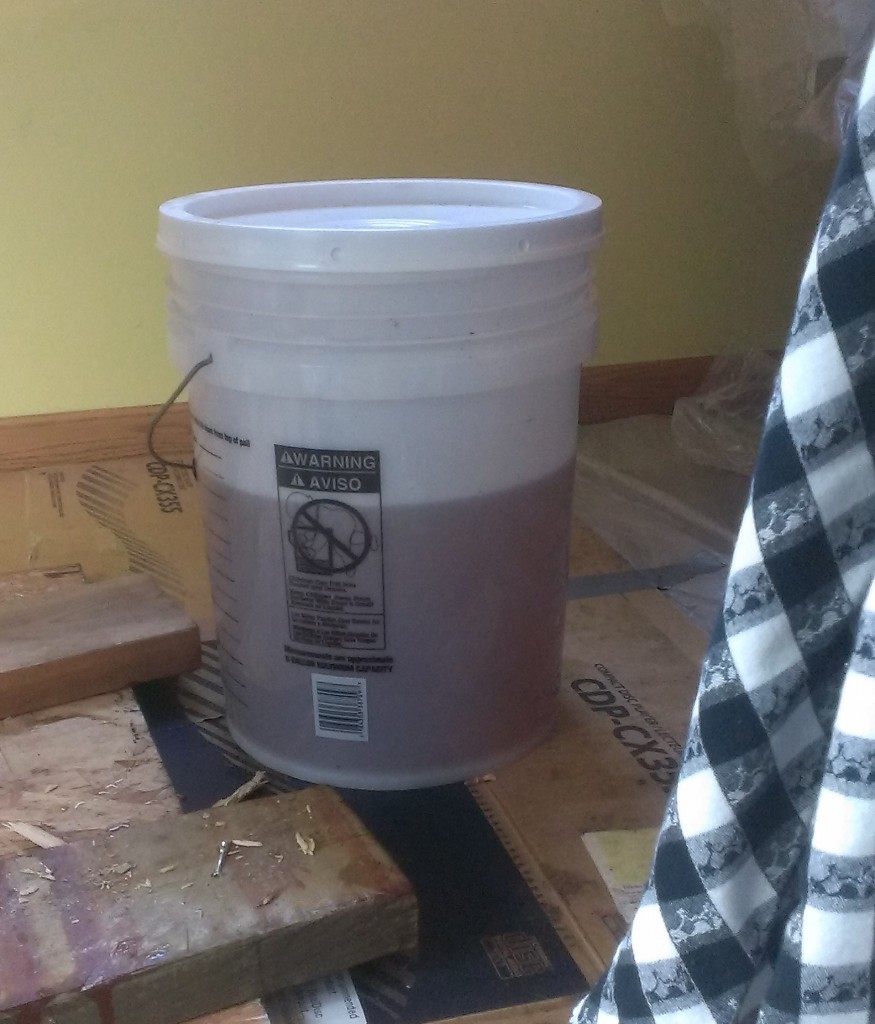

(the 19% pail)

Anyhow Kate and I had to wrestle with a water content problem in our last pail of honey. It had a too much, 19%. Checking various websites and forums discouraged even trying to dry it below 18.6% without professional drying rooms. With determination though we found a technique that involved lowering the water content of 10% of the whole to 15%, then mixing it back in. Kate hit on using the convection fan in our oven along with the 120 degree heat necessary. We used a shallow glass pan and after 12 plus hours lowered the water content in the pan to 14.8 or so.

After mixing it back into the larger quantity, we achieved a reading much more in line, 17.5%. We had another quantity filtered out of the cappings which also had a higher than desirable %, 19 like the other batch. So we poured it in to the rest and achieved an 18.2% reading. Perfect.

We had to order another 48 1 pound containers. We’ve got a lot honey. We’re going to sell it this year for $8.00 a pound. This is raw honey, no chemicals (hopguard is a food additive). Plus, it’s artisanal, produced in small batches. If you want some, send me an e-mail or comment on this article.

Lughnasa Honey Moon

Today, bottling and washing. Storing. The cappings are in the sun where the heat helps the honey left behind escape into a bin below. The bees, smelling the honey, have gathered around the lip of the cappings tank. In the process of cleaning the extractor I got some honey on me and the bees began buzzing, trying to land, get what I had. I went inside.

Kate and I both got up wincing a bit this morning. Just before lights out last night, Kate said, “Good thing we don’t have to earn our living through manual labor.” Yep.

Although. The tiredness from this kind of work has a satisfying quality, earned in a good cause. A certain works righteousness goes with the Protestant work ethic. Thanks, Max Weber and John Calvin.

Lughnasa Honey Moon

The colony as honey highrise before extraction. Kate’s homemade super covers are on the ladder.

The equipment washed and ready. From top left, uncapping tank, extractor barrel, five gallon pails with our three filters, extractor stand in process.

My handy wife at work creating a stable platform for our indoors extracting.

The extractor in the kitchen.

Kate’s dextrous work with the uncapping knife made extraction much easier.

The result, two pails this full, plus some left yet in the barrel and in the uncapping tank. Our hair dryer innovation pictured here.

What are mommy and daddy doing now?

Lughnasa Honey Moon

We harvested four supers of honey under the honey moon. Kate and I worked all day,  until about 6:30 pm to extract the honey from 36 frames with honey on both sides. Pulling the supers went much more easily this year since I used a gentle chemical that bees don’t like to get the bees to leave the super. I loaded them on a pallet and covered them with cloth covers Kate made yesterday.

until about 6:30 pm to extract the honey from 36 frames with honey on both sides. Pulling the supers went much more easily this year since I used a gentle chemical that bees don’t like to get the bees to leave the super. I loaded them on a pallet and covered them with cloth covers Kate made yesterday.

This was the first year we ran the extractor in the kitchen, rather than on the deck. We wanted to reduce the number of bees coming to the extraction. The chemical, the super covers and extracting inside all helped. We had only a few bees and they were ones who had not vacated the supers before I removed them from the colony. Success on that front.

But. We air condition our home as some of you know. Honey at 90 degrees flows smoothly out of the supers and into the extraction tank. At 65 degrees, not so much. The first six frames took over a half an hour. We would have been at this well into the night. So.

Kate stepped up her uncapping skills which helped us get to all the honey, fast. We debated taking the extractor outside on the deck, but that would mean we couldn’t keep  the honey gate open and let the honey flow directly into a bucket. We thought about the garage, but before we made a decision, we decided to give it one more try with Kate’s new uncapping process and a second innovation, a hair dryer stuck into the extractor while it was working.

the honey gate open and let the honey flow directly into a bucket. We thought about the garage, but before we made a decision, we decided to give it one more try with Kate’s new uncapping process and a second innovation, a hair dryer stuck into the extractor while it was working.

There we go. We got our time for six frames down to around 10-12 minutes. Much better. I estimate that we have between 65 and 75 pounds of honey, our best year ever and one resulting from a package hived in April. Extraordinary, especially considering the very cool spring.

Tomorrow is clean up and bottling, then storing the extracting equipment for next year.

Feels good to be done. (though. there are still two supers on the colony because the nectar flow might not be quite over.)